What is polished concrete?

Polished concrete is created through a mechanical process by profiling/honing concrete with a 10-12 step process utilizing Sase tooling and chemical treatments. Tsp is trained and certified in SASE Signature Floor Systems, machines and applications. Polishing concrete is process a very labor intensive process that has progressive stages from initial preparation by grinding/profiling, to honing the surface using progressively finer Sase diamond tooling and quality chemical treatments. Polished concrete is easy to clean and maintain due to its smooth, even surface that resists dirt and stains. Unlike other flooring options, it does not have grout lines where debris can accumulate. Its durability allows for the use of commercial cleaning equipment without damage, and it’s ready for immediate use after cleaning, minimizing downtime. Routine maintenance typically requires only basic cleaning tools and a neutral pH cleaner, making it a cost-effective and hassle-free flooring choice. This also helps maintain proper hygiene standards due to polished concrete floors do not trap dust, dirt, and allergens like carpet and other flooring options. This can improve air quality in creating a healthier environment in any enclosed area Polished concrete is an environmentally friendly and sustainable flooring option that can help reduce your carbon footprint while providing a durable, long-lasting, and low-maintenance flooring solution for your commercial or residential space. Made from natural materials, such as cement, aggregate, and water, polished concrete does not emit any harmful chemicals or VOCs. This also makes polished concrete a healthier and safer choice for workers and the environment. In addition, the low maintenance requirements of polished concrete compared to other flooring systems generates less waste, uses few chemicals, and reduces the need for replacements or repairs.

- Industrial Polished Concrete

- Showroom Polished Concrete

- Cream Polished Concrete

- Modern Polished Concrete

- Full Aggregate Exposed Polished Concrete (rock/stone exposure)

Advantages

- Highly resistant to contaminants: The dense, polished surface prevents oil and other substances from easily penetrating the concrete.

- Durable against heavy traffic: Resists tire marks from forklifts and other heavy machinery.

- Enhanced strength and abrasion resistance: 40% more abrasion resistant than untreated concrete.

- Improved light reflection: Provides a 30% increase in ambient light reflection compared to unfinished concrete.

- Impact resistant: Offers 20% greater impact resistance than standard concrete.

- Flatter surface: Creates a smoother, more level floor.

- Safety compliant: Meets OSHA recommended static coefficient of friction (SCOF) for polished surfaces.

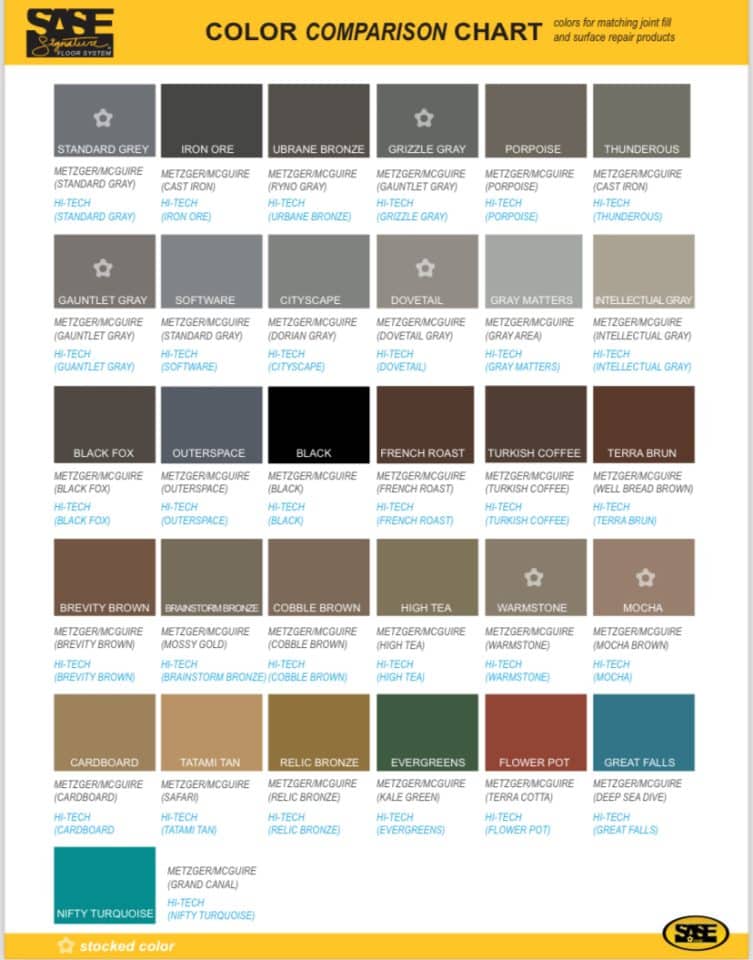

- Color customization: Ability to add color to existing concrete during the SASE Signature Floor application.

Polished Concrete Floor Alternatives

In addition to mechanically polished concrete floors, there are alternative, more affordable options that look similar like exposed sealed concrete, chemical polished concrete, or burnished concrete floors. However these floors do not deliver the benefits of mechanically polished concrete.

Grind And Seal

What Are Grind and Sealed Concrete Floors?

Grind and sealed concrete floors are exactly like its name – the process involves grinding the concrete surface, then sealing with a topical sealer.

Here are the steps for grind and sealed concrete:

- 1. Profile/grind concrete to remove any contaminants from the existing slab.

- 2. Repair/fill cracks and divots quoted from specs and or customer expectations.

- Depending on your floor goals (i.e. desired finish and durability requirements), the concrete may be ground again with finer diamonds to further smooth the floor. If the concrete is soft, porous or free of contaminants, a second pass may not be necessary.

- 3. Floor/substrate is cleaned by Hepa approved vacuums and or auto scrubber

- If desired, at this step a stain color can be added to your grind and sealed concrete floor. Choose from a wide variety of colors, from neutral, earth tones to colorful concrete dyes.

- Lastly, your sealed concrete floor is sealed with a topical sealer. Depending on your floor goals, requirements, and your space, we will recommend the best type of sealer for your project.

Sealed concrete floors have emerged as a popular flooring trend in both commercial and residential spaces. They offer not only aesthetic appeal but also durability, longevity, affordability, environmental friendliness, and versatility for various applications such as businesses, warehouses, retail spaces, homes, restaurants, breweries, and art galleries. The desired finish of sealed concrete can range from a subtle low sheen to a stunning high gloss resembling glass.

When exploring options for exposed concrete flooring, you may encounter flooring companies that provide both polished concrete and sealed concrete solutions. This can lead to questions about which option is best suited for your project and space, as well as what sets them apart. While both polished concrete and grind and sealed concrete floors offer excellent flooring solutions and can appear almost indistinguishable, there are noteworthy differences between them. Polished concrete has more steps and begins the refining process in the beginning by densifying the concrete Surface at Different Levels Ensuring Hardening of the Wear Surface Regardless of Porosity. Sealed concrete floors are treated topically and are usually 3 steps depending on the condition of the concrete.

Why Sealed Concrete?

Durability: Sealed concrete floors are highly durable and can withstand heavy foot traffic, impact, and abrasion. They are resistant to stains, chemicals, moisture, and other types of damage, making them ideal for both commercial and residential spaces that experience high usage.

Longevity: Concrete sealer helps extend the lifespan of the flooring by providing a protective barrier. Sealing concrete floors helps prevent cracks, spalling, and deterioration, ensuring that the floors maintain their appearance and functionality for an extended period.

Low Maintenance: Sealed concrete floors are relatively low maintenance compared to other flooring options. The sealed concrete surface is easy to clean and requires minimal effort for routine maintenance. It resists stains and can be easily wiped or mopped, making it a convenient choice for busy commercial spaces or homes with high foot traffic.

Versatility: Sealed concrete floors offer versatility in terms of design options. Various sealers are available in different finishes, including matte, satin, or high gloss, and allow you to achieve the desired aesthetic for your space. Choose from a range of colors, concrete stain/dye, and decorative treatments to customize the appearance of the floor.

Cost-effective: Sealed concrete floors are cost-effective as they use the existing concrete surface. The initial installation cost of sealed concrete floors is often lower compared to other flooring options making it a budget-friendly choice for both commercial and residential settings.